Description

Ironstone® Grand Series Pro Chef Knife AUS-10

Starting with Australian Iron Ore was something that really set the stage for us to engineer a knife that was Australian, literally to the core.

We chose the iconic Frill Necked Lizard to represent the brand, a local of the Ironstone ranges of Western Australia.

OUR STORY

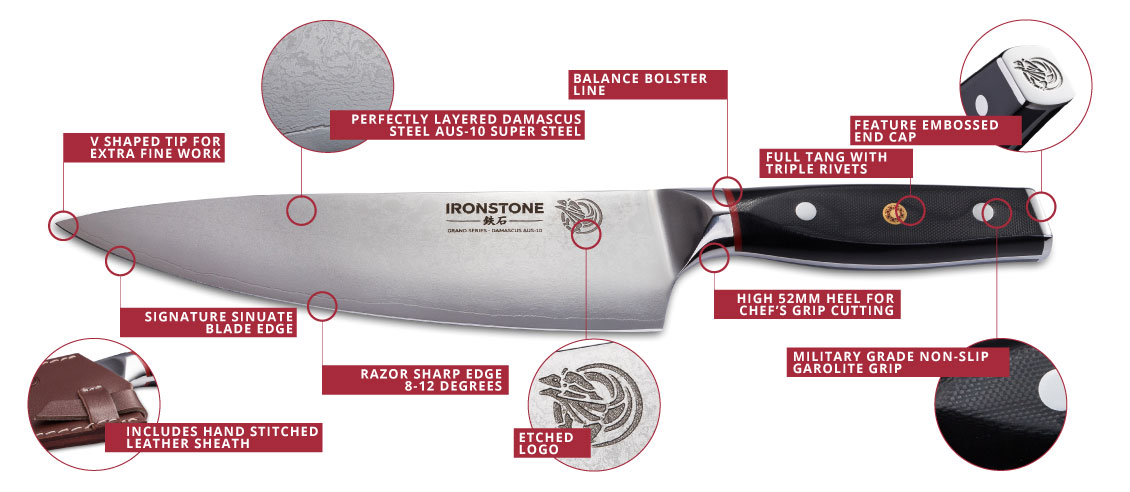

The steel that makes the blade is Aus-10 and is often referred to as wonder steel because when cast into a knife it exhibits the most desirable traits of high corrosion resistance, incredible hardness and excellent edge retention. The Aus-10 steel used is smelted in Japan. This process involves engineering a stainless steel of very specific percentages of carbon, manganese, molybdenum and vanadium to create a proprietary steel perfect for ultra premium knives. The final forging process of actually crafting the knife is completed to ISO 9001 QA Standards by expert blade smiths in a world class knife factory in mainland China.

Beauty was also a driving factor in our design. That’s why you’ll see the blade has an incredibly delicate and detailed Damascus pattern. This finish, called Pattern Welding, is created by layering the steel and forging it together over and over. In fact, this knife has been layered and forged up to 70 times to create a unique pattern that is imbued into the blade right to its very core.

Something of particular note with each Ironstone knife is the sinuate. This is the line separating blade from the cutting edge. Each sinuate is unique. This is because the process of honing is done by hand which makes no two knives the same, each one is literally a work of art, distinct from any other.

This honing method is known as the Honbazuke Method and is essentially done in three stages.

- Stage one is where the blade is ground on a lubricated rotating sharpening stone to bring the edge down to approximately 30∞.

- Stage 2 is much more precise and only the most skilled craftsmen and women are allowed to perform this task. Here the crafts person hones the shoulder of the blade back from the edge using a horizontal sharpening stone. Not unlike cutting diamonds, this process requires great concentration and skill. This is where you can see the slight variations in the sinuate making each knife, like each hand-cut diamond, unique.

- Stage 3 is done using a leather strop which removes the minute bevel of the edge giving it that razor-sharp finish.

Finally, once the blade has been inspected under a microscope to ensure it is within exact tolerances, the blade is tempered in a process called Cryogenic Quenching. In this step the entire blade is immersed in liquid nitrogen, a treatment which imparts very high wear resistance to the steel.

The spine thickness of the blade is just 2mm thick (with full tang) which minimises resistance when slicing as the surgically sharp edge leads the blade through to the board. The blade tip or point has also been carefully designed allowing you to carry out the very finest of work.

The final hardness of Aus-10 Steel has been tested on the Rockwell hardness scale (HRC) at 62/69 +/- 2%. Any harder and chipping of the edge can occur. Any softer and it could not hold such a surgical sharp edge.

Don’t concern yourself with regularly sharpening this knife. The edge itself has excellent retention and over time we recommend using a 6000/1000 stone to keep it super sharp. All it takes are a few strokes each side and the job is done. ** If you don’t already have one of these stones, use the Discount Voucher in the box to get a great deal.

Likewise, if you prefer a forward-thrust to cut then again this can be achieved. Because this is a sophisticated technique, we encourage you to contact us about this rather than us go into intricate detail here. The point is, this knife will slice through virtually anything you put in front of it.

This is a big knife with a 60/40 balance ratio along the red line which delineates the handle from the bolster. Think of it as a tractor where all the muscle is out-front while you control it from the rear.

To handle this knife, you should master the pinch-grip. This is where the thumb grasps the beveled bolster on one side and the fore-finger on the other. The heel of the knife is 45mm making this perfect for the task. Using this grip gives excellent control of the entire knife all the way to the tip.

THE HANDLE

The handle of this knife is also unique to the Ironstone Grand Series. After talking with many professional chefs, we crafted a handle that is 35 % larger (30mm x 22mm) than handles of similar knives in this category because the feedback was that a broader handle with a deeper ballast felt more stable in an adult’s hand. The central section of the handle then slopes inwards toward the diagonal bolster and the back-sloped butt which gives the most natural grip. Again, we’ve had the Frill Necked Lizard engraved on the end cap.

The material used as the handle is Garolite, an incredibly hard composite material similar to carbon fibre and favoured for its high strength, low moisture absorption, electrical insulation and resistance to chemicals and staining. It is the same material used by the military for the hand grips on precision weapons. Three rivets with the central one being a feature secure the handle to the full tang.

FEATURES

To summarise the key features of this beautiful instrument:

- Aus-10 Wonder Steel comprised of vanadium for edge retention and chromium for corrosion resistance.

- Vacuum heat-treated central Aus-10 core.

- Folded layered core of up-to 70 layers creating an ultra-fine Damascus pattern.

- Blade cryogenically quenched in liquid nitrogen at a temperature of -185∞ to harden and strengthen the chromium within the stainless-steel alloy. For maximum wear resistance.

- Hand polished edge and signature sinuate on each blade.

- An almost impossible 8-12∞ edge.

- 64/69 +/- 2% on the Rockwell (HRC) hardness scale. Any harder and chipping of the edge can occur. Any softer and it could not hold such a surgical edge.

- Full Tang handle with triple riveted non-slip Garolite grip.

- Feature bolster band delineating 60/60 centre of gravity.

- 45mm heel designed to be used in a pinch-grip.

- -shaped tip for high-precision work.

- Did we mention a surgically sharp blade?

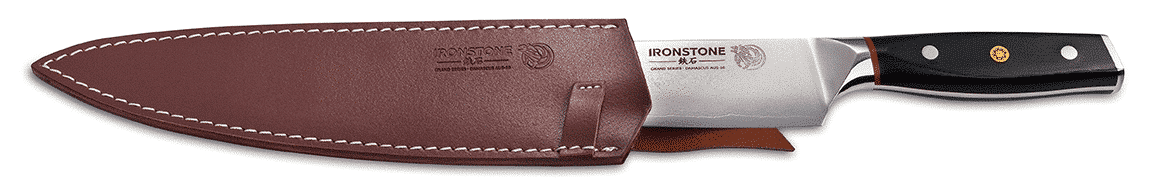

- Hand stitched, branded leather sheath with tongue for storage and edge protection.

Included with your package:

- Ironstone® Grand Series Pro Chef Knife

- Leather sheath

- Branded polishing cloth

- Instruction booklet

- Discount voucher for future purchases at The Perfect Steak Company.

WARRANTY INFORMATION

Naturally, the Ironstone Grand Series knife range comes with a full 30 Day Money Back Guarantee and we extended a 7 Year Workmanship Warranty.

The Perfect Steak Company extends manufacturers warranties on the range goods it sells as per manufacturers instruction. The Ironstone Grand Series comes with a 7 Year Workmanship warranty which does not cover damage caused by fair wear and tear, abnormal storage conditions, incorrect use, accidental misuse, abuse, neglect, misapplication or modification. In the event of a Warranty Claim, please contact The Perfect Steak Company first. We will advise how best to proceed. Important additional information is also shown on our Warranty’s Page.

FINAL COMMENTS

We’ve invested greatly in creating a knife which we want you to love more than any knife you’ve ever owned, or ever will. We want it to be a feature piece of your kitchen, home cook or pro-chef alike. We want you to love using it and every time you handle it to enjoy the pure please of having such a refined tool at your disposal.

Ironstone® Grand Series Pro Chef Knives are a work of art, born from a passion to craft a uniquely Australian knife, proud to feature in the most prestigious kitchens. Ultimately though, what you’re investing in is a tool that is simply a pleasure to use, day after day, year after year.

Customer –

This is a really well made knife, you can feel the care on details used for build it. I can compare this knife to more expensive German ones, even double the price, with no difficulty at all.

Customer –

really nice design , love it!

Customer –

Check it out!! I love my new knife – it cuts great. Looks and feels like it is well made. Very fancy!!

Customer –

These knives are handy and super sharp. Handle fits nicely in your hand and is very comfortable. I ordered both the sizes 8″ and 9.5